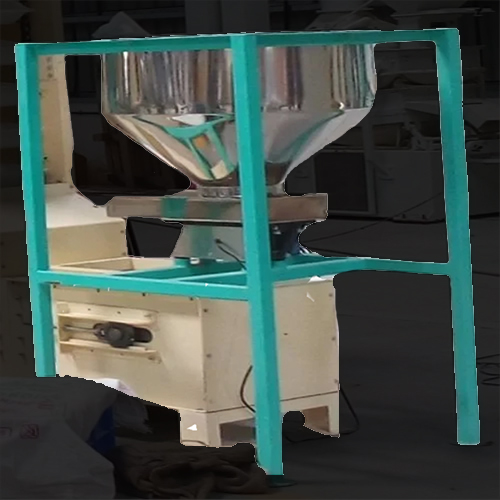

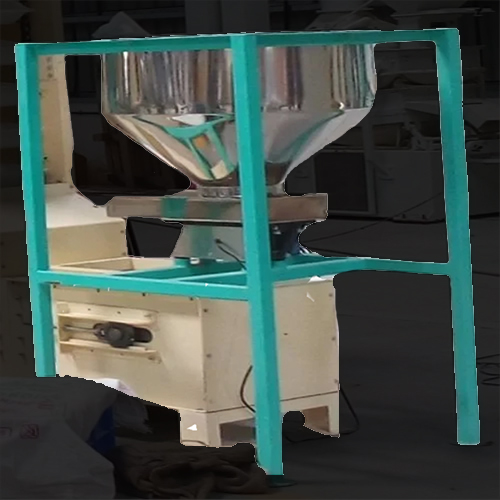

Vibratory Feeder

Vibratory Feeder :

The Vibratory Feeder is a versatile and efficient piece of equipment designed to facilitate the smooth and controlled feeding of bulk materials in a variety of industries, including food processing, pharmaceuticals, chemicals, mining, and recycling. Utilizing advanced vibration technology, our vibratory feeder ensures consistent material flow, reducing blockages and minimizing downtime in your production line.

- Precise Feeding Control: Equipped with adjustable vibration settings to provide accurate control over feed rate, ensuring a steady and reliable flow of materials.

- Efficient Material Handling: Ideal for handling a wide range of materials, including powders, granules, flakes, and other bulk solids, the vibratory feeder reduces spillage and maintains material integrity.

- Durable Construction: Built from high-quality materials such as stainless steel or carbon steel, the feeder is designed to withstand heavy-duty use in demanding industrial environments.

- Low Maintenance: With minimal moving parts and a robust design, the vibratory feeder requires less maintenance, reducing downtime and operational costs.

- Versatile Design: Available in various sizes and configurations, including open or enclosed trough designs, to accommodate different materials and applications.

- vEasy Integration: Compact and customizable to fit seamlessly into existing production lines, the feeder offers flexible installation options to suit your operational needs.

- Quiet Operation: Designed for low noise output, making it suitable for environments where noise reduction is a priority.

- Energy Efficient: The vibratory feeder operates on low energy consumption, providing an economical solution for continuous feeding processes.

- Sanitary Options Available: For applications requiring strict hygiene standards, the vibratory feeder can be customized with food-grade materials and finishes, making it ideal for food and pharmaceutical industries.

- Safety Features: Equipped with emergency stop buttons and protective guards to ensure safe operation for both operators and equipment.

Whether you are looking to handle fine powders or larger bulk solids, our Vibratory Feeder provides a reliable, efficient, and customizable solution to optimize your material handling processes. Designed with precision and durability in mind, this feeder ensures smooth and consistent feeding, enhancing the overall efficiency of your production line.

- Material of Construction: Stainless steel, carbon steel, or food-grade stainless steel.

- Feed Rate: Adjustable; typically ranges from 0.1 to 50 cubic meters per hour.

- Trough Width: Customizable; standard widths range from 100 mm to 1,200 mm.

- Trough Length: Customizable; typically ranges from 0.5 meters to 3 meters.

- Vibration Frequency: Adjustable; typically 50 to 60 Hz.

- Amplitude: 1 to 5 mm, adjustable to suit material properties.

- Drive Type: Electromagnetic or electromechanical drive options.

- Power Supply: 220V/380V, 50Hz/60Hz.

- Noise Level: Below 75 dB.

- Operating Temperature Range: -20°C to 80°C (materials dependent).

- Mounting Options: Suspended, base-mounted, or custom configurations.

- Cleaning: Easy-clean design with options for quick-release trays and tool-free maintenance.

- Compliance: Meets CE, FDA, and GMP standards.

- Safety Features: Emergency stop buttons, protective guards, and overload protection.

- Optional Accessories: Covers, screens, liners, and hoppers.

- Control Options: Manual, remote, or PLC-controlled for automated operation.