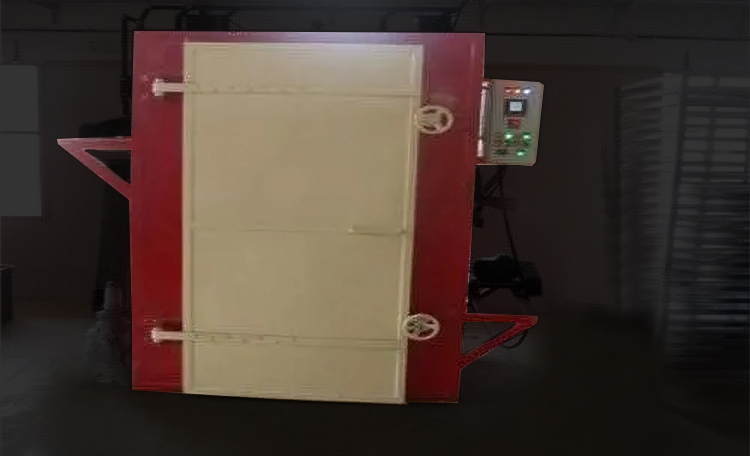

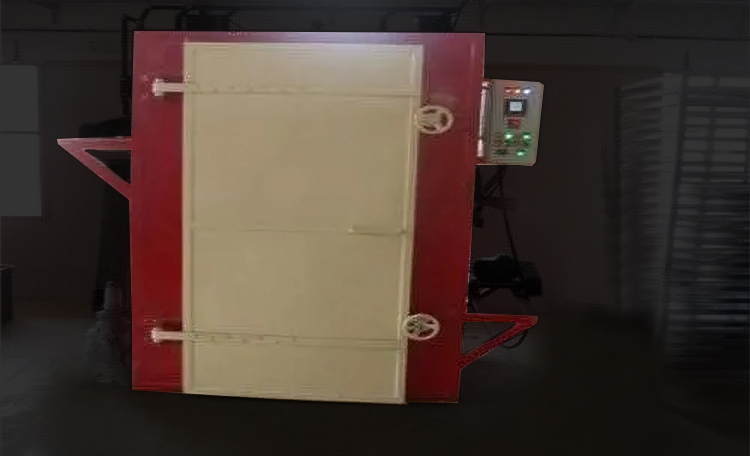

Tray Dryer

Tray Dryer :

The Tray Dryer is a highly efficient drying system designed for drying bulk quantities of various materials using a controlled and uniform heat source. It is widely used in industries such as pharmaceuticals, food processing, chemicals, and textiles for drying powders, granules, herbs, and other sensitive products. With its ability to maintain consistent temperature and airflow, the Tray Dryer ensures uniform drying, high product quality, and improved operational efficiency.

- Uniform Drying: The Tray Dryer features a series of trays arranged within a controlled drying chamber. Heated air circulates uniformly across all trays, ensuring consistent drying of the materials and preventing issues such as uneven drying or product degradation.

- Adjustable Temperature Control: Equipped with precise temperature control mechanisms, the Tray Dryer allows for accurate adjustment of drying temperatures to suit different materials and drying requirements. This feature is crucial for preserving the quality and integrity of heat-sensitive products.

- Efficient Airflow System: The dryer utilizes a well-designed airflow system to ensure effective heat transfer and moisture removal. The uniform distribution of air across the trays enhances drying efficiency and reduces drying times.

- Versatile Applications: Ideal for drying a wide range of materials, including pharmaceutical products, food items, chemical powders, and herbal extracts. The Tray Dryer’s versatility makes it suitable for various industries with diverse drying needs.

- Durable Construction: Constructed from high-quality materials such as stainless steel or mild steel with anti-corrosive coatings, the Tray Dryer is built to withstand the demands of continuous industrial use. Its robust design ensures long-lasting performance and reliability.

- Energy Efficiency: Designed to operate with minimal energy consumption while maintaining high drying efficiency. The Tray Dryer’s energy-efficient operation helps to reduce operational costs and environmental impact.

- Easy Maintenance: The Tray Dryer is designed for easy cleaning and maintenance, with removable trays and accessible components that simplify the cleaning process and reduce downtime.

- User-Friendly Operation: Features an intuitive control panel for setting and monitoring drying parameters, including temperature, time, and airflow. The user-friendly interface enhances operational convenience and control.

- Safety Features: Equipped with safety interlocks, over-temperature protection, and other safety mechanisms to ensure safe operation and protect both operators and equipment.

- Hygienic Design: Available in sanitary designs with smooth surfaces and easy-to-clean features, making it suitable for applications with strict hygiene requirements, such as in the food and pharmaceutical industries.

The Tray Dryer offers a reliable and efficient solution for drying a wide range of materials in various industries. With its advanced features, durable construction, and user-friendly operation, the Tray Dryer ensures high-quality drying results and enhanced operational efficiency.

- Material of Construction: Stainless steel, mild steel with anti-corrosive coatings

- Number of Trays: Typically ranges from 6 to 24 trays, depending on model and capacity

- Tray Size: Customizable; common sizes include 600 x 800 mm, 800 x 1,200 mm, etc.

- Tray Spacing: Adjustable; typically ranges from 50 mm to 150 mm between trays

- Drying Chamber Dimensions: Customizable; varies based on model and number of trays

- Heating Source: Electric, steam, or gas-fired heating options

- Temperature Range: Typically from 30°C to 150°C; adjustable to suit different materials

- Temperature Control: Digital or analog temperature controllers with high precision

- Airflow System: Forced air circulation with adjustable fan speed

- Airflow Type: Horizontal or vertical airflow, depending on model

- Drying Capacity: Up to 2,000 kg per batch, depending on tray size and material properties

- Power Supply: 220V/380V, 50Hz/60Hz

- Power Consumption: Ranges from 3 kW to 30 kW, depending on size and heating source

- Noise Level: Below 85 dB

- Control Options:Manual, digital control panel, or PLC-controlled for automated operation

- Safety Features: Safety interlocks, over-temperature protection, and emergency stop functions

- Maintenance: Easy access for cleaning and maintenance; removable trays

- Dimensions: Customizable; varies based on model and capacity

- Weight: Typically ranges from 500 kg to 3,000 kg, depending on size and configuration

- Hygienic Design Options: Available in food-grade and sanitary designs with smooth, easy-to-clean surfaces

- Compliance: Meets CE, FDA, and GMP standards