Capacity

Customized

Brand

Micron

Colour

Green

Automatic Grade

Semi-Automatic

Design

Customised, Standard

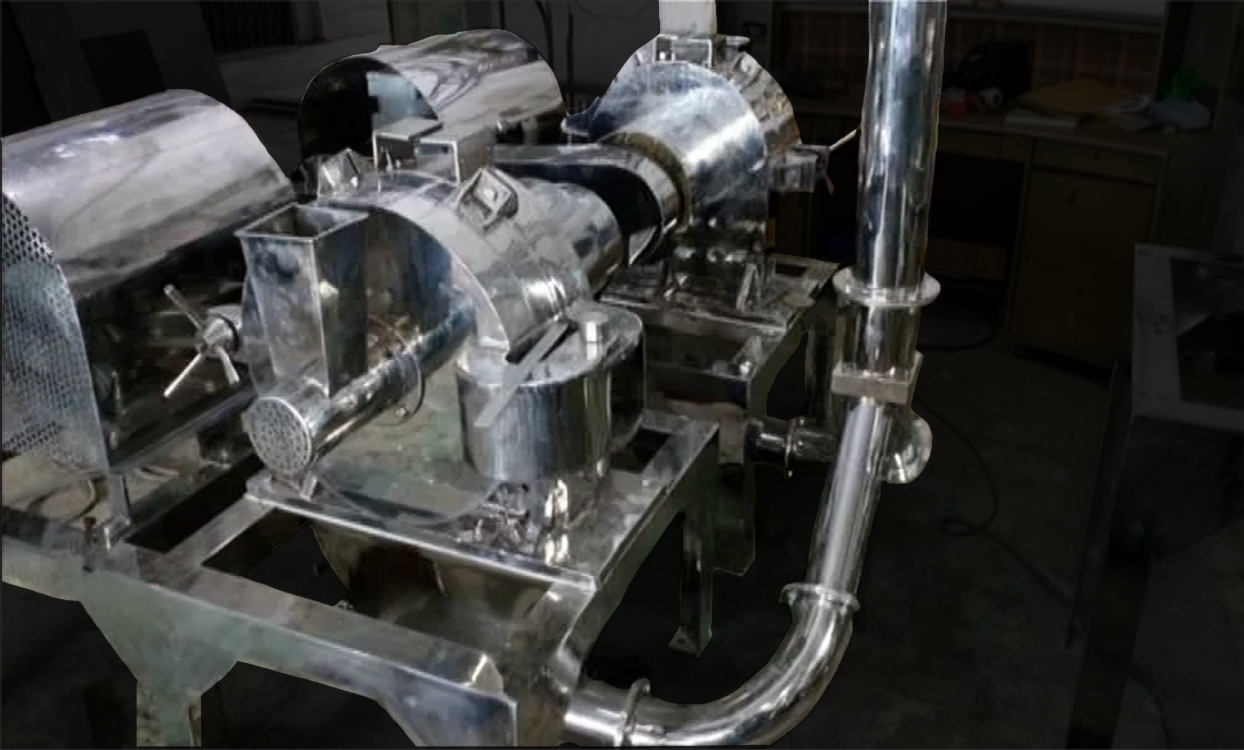

"Welcome to the future of sugar flavor enhancement with our cutting-edge Automation Technology Sugar Milling System. We understand the pivotal role that sugar flavor plays in your product, and we're here to revolutionize the way you achieve it."

Our Sugar Milling Systems are at the forefront of precision and efficiency, delivering perfectly ground sugar particles that enhance the sweetness and texture of your product like never before. With advanced automation features, you can say goodbye to manual milling processes that are prone to inconsistencies and hello to a streamlined, reliable solution.

What sets our Sugar Milling System apart is their ability to finely tune the milling process to meet your exact specifications. Whether you require a coarse or ultra-fine grind, our machines deliver unmatched precision, ensuring that every batch of sugar contributes to the exceptional flavor profile of your product. But efficiency doesn't mean sacrificing quality. Our machines are engineered with precision and durability in mind, utilizing state-of-the-art technology to achieve optimal milling results while minimizing energy consumption and waste. Experience the difference that Automation Technology Sugar Milling System can make in elevating your sugar flavor to new heights. Contact us today to learn more about how our innovative solutions can transform your production process and set your products apart in the market.

Micron Sugar Milling System, designed to meet the diverse needs of the food industry. This versatile system can grind various grades of sugars, such as M or S, from coarse to super-fine fineness, making it perfect for a wide range of applications.

Our sugar milling systems are engineered for capacities ranging from 100 kg/hr to 4000 kg/hr, offering scalable solutions for both individual equipment and completely automated milling plants.

This streamlined process ensures both the quality of the ground sugar and the safety of the operation, making the MIcron system both efficient and secure

Sugar Milling System have a wide range of applications across various industries. Here are some of the key applications