Size Reduction Equipment

High-Efficiency Size Reduction Equipment, Precision Solutions for Particle Size Control.

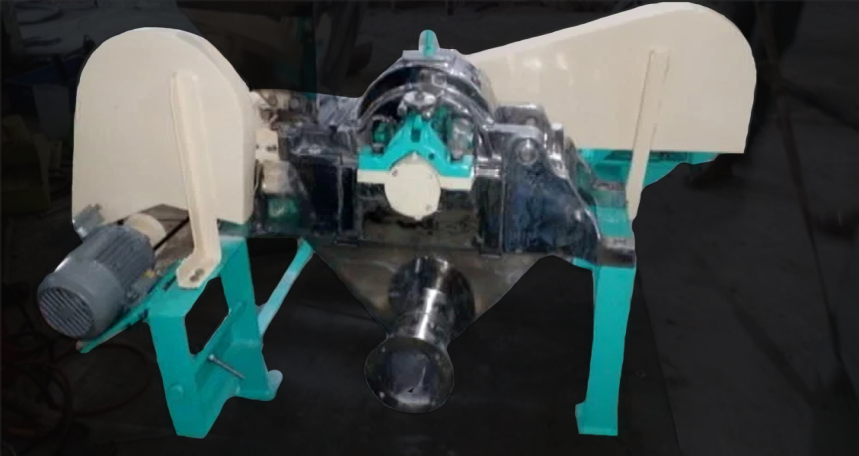

Industrial Chopper

The Industrial Chopper is a robust and high-performance machine designed for the precise cutting, chopping, and size reduction of a wide variety of materials in industrial applications.

Industrial Hammer Mill

Hammer mill A rotor is attached with swinging or stationary hammer heads, which rotate at a high speed to force the ingredients against a circular screen or a solid serrated section, resulting in crushing of material inside a hardened casing (Figure 2.1). The crushed materials are further crushed until they reach the size of the aperture of a hard metal sieve at the outlet.

Pin Mill

These mills have two discs with orderly placed pins to impart high-impact and shear forces for size reduction. One disc is the stator disc and the other is the rotary disc (Figure 2.3). A consistent and uniform quantity of material is gravity fed through the centrally located inlet of the stator disc.

Ultra Fine Mill

The Ultra Fine Mill is an advanced grinding machine designed to produce extremely fine powders for a variety of industrial applications. With its ability to achieve high levels of precision and consistency, this mill is ideal for industries such as pharmaceuticals, cosmetics, food, chemicals, and minerals that require ultra-fine particle sizes.

Micro Pulverizers

Micro Pulverizers are advanced grinding machines designed for pulverizing a wide range of materials into ultra-fine powders. Ideal for industries such as pharmaceuticals, food processing, chemicals, and minerals, these pulverizers are engineered to deliver high-performance grinding with precise particle size control.

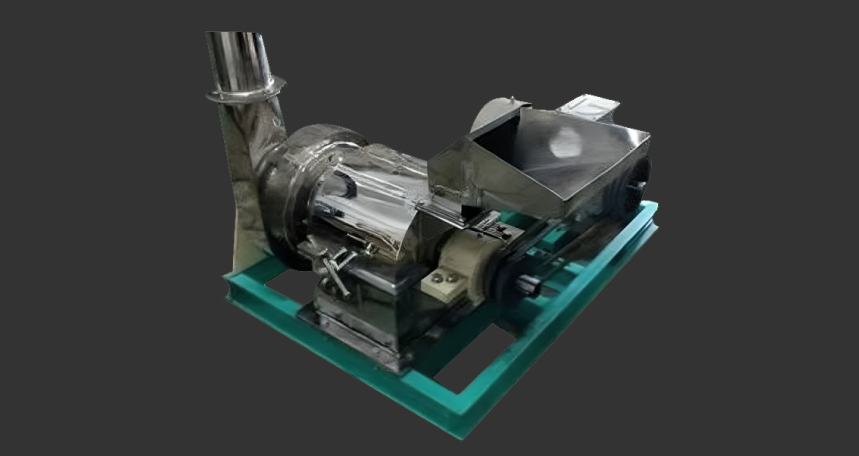

Air Swept Mill

The Air Swept Mill is a sophisticated grinding machine designed to achieve precise particle size reduction through a combination of impact and air classification. It is widely used in the chemical, pharmaceutical, food, and mineral industries for processing materials into fine powders. The mill’s design integrates air flow with mechanical grinding, enhancing the efficiency of particle size control and ensuring high-quality product output.