Plastic Powder

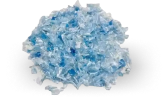

Plastic Flakes

Plastic Fragments

Plastic Granules

Plastic Pellets

Plastic waste is a growing concern worldwide due to its detrimental impact on the environment. In recent years, the use of plastic grinder machines has gained popularity as a solution to this problem. These machines help to break down plastic waste into smaller pieces, allowing for efficient recycling, manufacturing of new products, and energy recovery. With various sizes and designs available, plastic grinder machines have become an essential tool in many industries, including recycling, manufacturing, and construction. In this context, it is important to understand the function and benefits of plastic grinder machines in reducing plastic waste and preserving the environment

It is also known as plastic crusher machine. Plastic grinder machines typically use rotating blades to shred the plastic material into smaller pieces. The size and shape of the particles produced depend on the size and shape of the blades and the mesh size of the screen through which the particles pass. Some plastic grinder machines also use cooling systems to prevent the plastic from melting due to the heat generated during the grinding process.

With the help our diligent professionals, we are able to manufacture and supply a wide range of Plastic Grinder Machine that is widely used in numerous industries for grinding. Our diligent professionals use optimum quality components with the aid of contemporary techniques in the manufacturing of this machine. Our offered machine is duly checked against several measures of quality to eradicate any kind of flaw as per predefined industry standards.

The manufacturing process of a plastic waste grinding machine can vary depending on the specific type and design of the machine. However, some common steps involved in the manufacturing process include:

The manufacturing process of a plastic crusher machine requires specialized knowledge and expertise in mechanical engineering, fabrication, and assembly. It is essential to ensure that the machine meets the required performance and safety standards to ensure efficient and safe operation

| Automation Grade | Semi-Automatic |

| Usage/Application | Plastic Grinding |

| Capacity | 55 - 80 Kg/Hr |

| Blade Size | 18" |

| Phase | 3 Phase |

| Material | MS |

| Voltage | 440 V |

| Color | Blue & White |

| Blade Material | WPS |

| Type | Semi-Automatic |

| Motor Power | 20 HP |

| Power | 20 HP |

| Warranty | 1 Year |

| Number Of Blade | 6 |

| Output | 50 - 80 Kg/Hr |

| I Deal In | New Only |

| Model Name/Number | 1 |

| Minimum Order Quantity | 1 |

Plastic grinding machines are used to reduce plastic waste into small particles or flakes, which can be reused in various applications. Some of the advantages of plastic grinding machines include:

Plastic grinder machine or Plastic bottle crusher machines have a wide range of uses across various industries, including: