Pin Mill

Pin Mill :

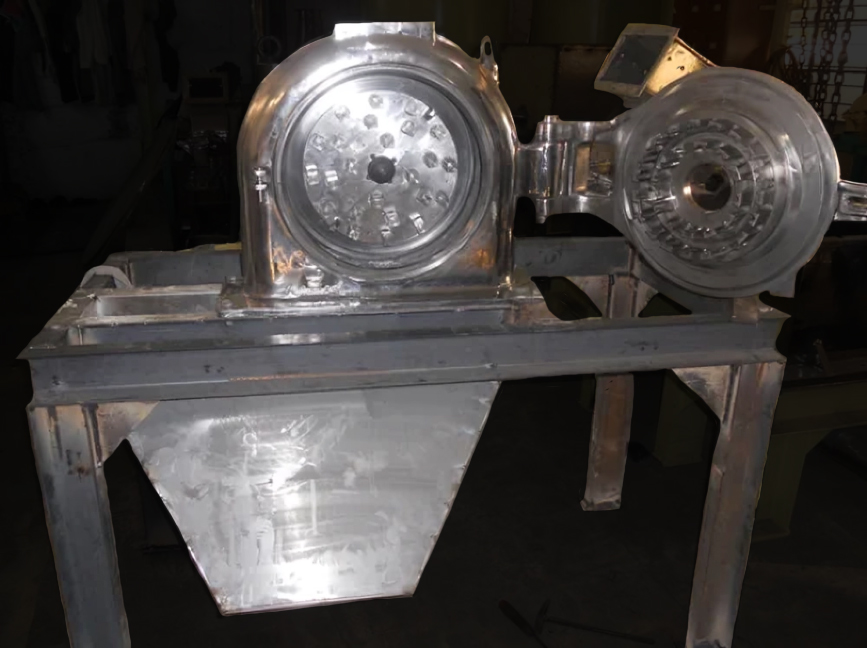

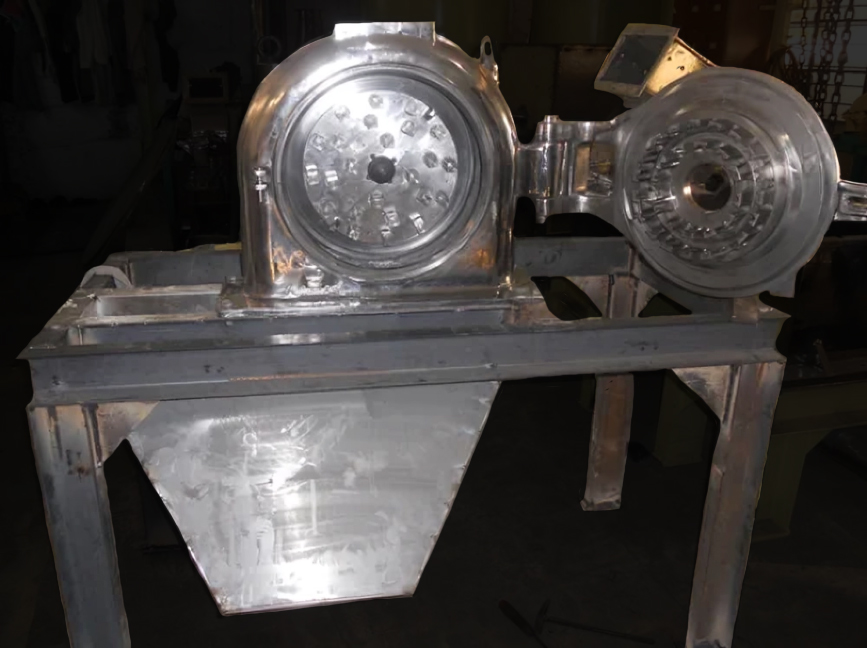

These mills have two discs with orderly placed pins to impart high-impact and shear forces for size reduction. One disc is the stator disc and the other is the rotary disc (Figure 2.3). A consistent and uniform quantity of material is gravity fed through the centrally located inlet of the stator disc. Centrifugal forces accelerate the materials in such a way that it reaches the impact zone. Control of the rotor speed helps to achieve the desired narrow spectrum of particle size distribution. Variation in the speed of rotor facilitates the mills to use it for coarse grinding or de-agglomeration as well as for fine grinding.

- Efficient Grinding Mechanism: The Pin Mill uses two counter-rotating discs fitted with intermeshing pins. The impact force generated between these pins allows for efficient and uniform size reduction, making the mill ideal for fine and ultra-fine grinding applications.

- Versatile Applications: Capable of processing a wide range of materials, including powders, granules, spices, grains, chemicals, minerals, and polymers. The mill's versatility makes it suitable for various industries requiring precise particle size control.

- Adjustable Particle Size:The Pin Mill features adjustable rotor speed and interchangeable pin designs, allowing for precise control over the final particle size, from coarse to ultra-fine. This adjustability ensures the mill can meet specific production requirements.

- Durable Construction: Built with high-quality materials such as stainless steel or carbon steel, the Pin Mill is designed to withstand the rigors of continuous operation, providing long-lasting durability and reliability.

- High Throughput: Engineered for high-capacity grinding, the Pin Mill can process large volumes of material quickly and efficiently, making it ideal for high-demand production environments.

- Easy Maintenance and Cleaning: Designed for easy access to internal components, the Pin Mill allows for quick cleaning and maintenance. This reduces downtime and ensures continuous operation, which is especially important in food and pharmaceutical applications.

- Low Energy Consumption: The mill is optimized for low energy usage while delivering high grinding efficiency, making it a cost-effective solution for continuous processing.

- Safety Features: Equipped with safety interlocks, overload protection, and emergency stop functions to ensure safe operation and protect both operators and equipment.

- Hygienic Design: Available in food-grade and sanitary designs with smooth finishes and easy-clean features, making it suitable for applications requiring stringent hygiene standards.

- Low Noise Operation: Designed to operate at reduced noise levels, the Pin Mill ensures a quieter working environment, enhancing operator comfort.

Technical Specifications :

- Material of Construction: Stainless steel, carbon steel, or food-grade stainless steel

- Rotor Speed: Adjustable; typically ranges from 3,000 to 14,000 RPM, depending on the model

- Motor Power: Ranges from 3 kW to 75 kW, depending on application and mill size

- Capacity: Up to 5,000 kg per hour, depending on the material and desired particle size

- Particle Size Range: Adjustable; typically from 20 microns to 200 microns

- Feed Size: Up to 10 mm, depending on the material properties

- Grinding Mechanism: Impact grinding with two counter-rotating pin discs

- Pin Material: Hardened steel, stainless steel, or tungsten carbide-coated pins

- Discharge Type: Gravity or pneumatic discharge options

- Power Supply: 220V/380V, 50Hz/60Hz

- Noise Level: Below 85 dB

- Operating Temperature Range: -20°C to 80°C (materials dependent)

- Safety Features: Safety interlocks, emergency stop buttons, and overload protection

- Maintenance: Easy access for cleaning and maintenance; tool-free disassembly options

- Control Options: Manual, remote, or PLC-controlled for automated operation

- Dimensions: Customizable; varies based on model and application

- Weight: Typically ranges from 300 kg to 2,500 kg, depending on size and configuration

- Hygienic Options: Sanitary design with smooth finishes for food and pharmaceutical applications

- Compliance: Meets CE, FDA, and GMP standards

- Optional Accessories: Feed hoppers, dust collectors, cooling systems, and soundproofing enclosures