Capacity

Customized

Brand

Micron

Colour

Green

Automatic Grade

Semi-Automatic

Design

Customised, Standard

Oleoresins are the flavour extracts obtained by the solvent extraction of the ground spices. Spice oleoresins represent the complete flavour profile of the spice. Oleoresins can replace whole/ground spices without impairing any flavour and aroma characteristic. All the spices contain essential oils in varying proportions which can be extracted by steam distillation.

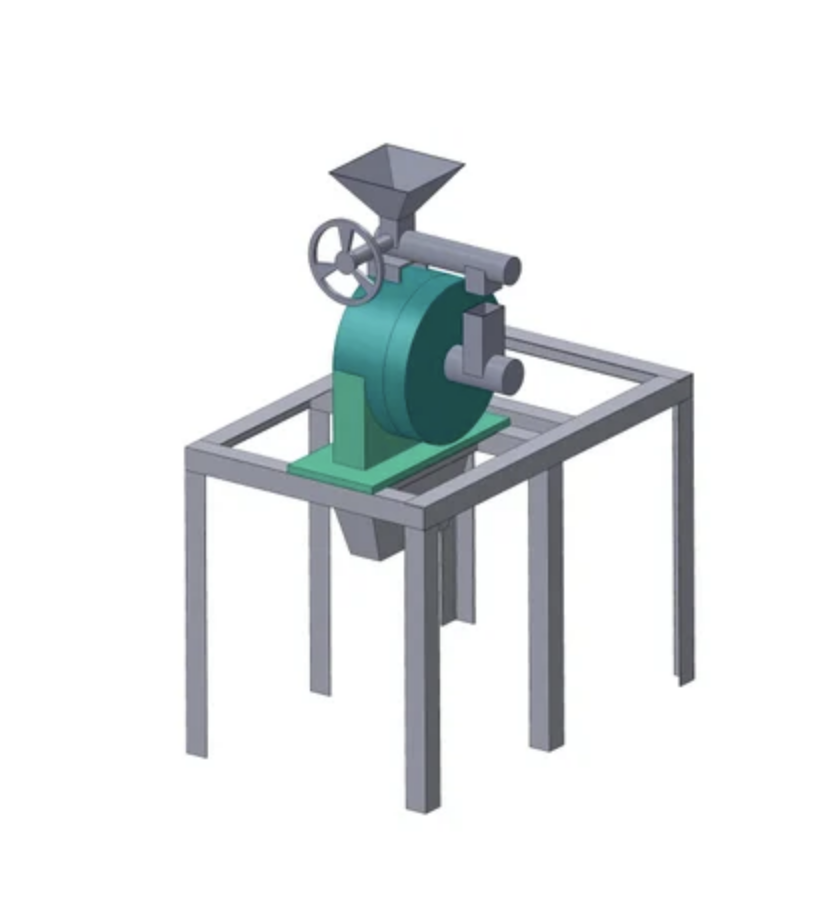

The raw spices like Balck pepller, Chilly, Cinnamon, Ginger etc., are cleaned and then ground to the required mesh size. Then extraction is undertaken with the help of proper solvent. Extraction is done by percolation of the solvent in percolator. Then the dark viscous extract of total soluble solids are drawn off and distilled under reduced pressure to remove the excess of solvent.

We are one of the leaders in supplying plant, machinery & technology for establishing herbal extraction & oleoresin manufacturing plants on turnkey basis. We specialize in the establishing phytochemical and herbal extraction plants for the extraction of essential nutrients, herbal medicines and any phytochemicals from various parts of a plant or tree like the leaves, the flowers, the seeds, the root, rhizomes, etc. These can also be used for fruit juice concentrations. Various products extracted are curcumin 95%, sennosides 20%-40%-60%, racemosus, polyphenols extraction from green tea, steviosides 90% etc. With oleoresin extraction plants extraction can be done by batch or continuous process. these plants are versatile enough to process any kind of spices like pepper, cardamom, ginger, clove, turmeric, paprika, red chilies, etc. These are designed to efficiently isolation of natural colours and bleaching of the resins to efficiently produce colourless resins with high pungency. Additional energy is not required during thermo syphon heating. It has zero effluent discharge system and is operated with scada software.

In the extraction process, a solute is transferred from one phase to another to separate it from unreacted starting materials or impurities. Extraction is also used to facilitate the isolation of a solute from a reaction solvent that is difficult to remove by evaporation, such as a solvent with a high boiling point

| Usage/Application | Industrial |

| Material | Stainless Steel |

| Capacity | 2 Ton/Day |

| Installation Services | Yes |

| Automation Grade | Automatic |

| Power Source | Electric |

| Voltage | 415 V |

| Frequency | 50 Hz |

| Minimum Order Quantity | 1 Piece |