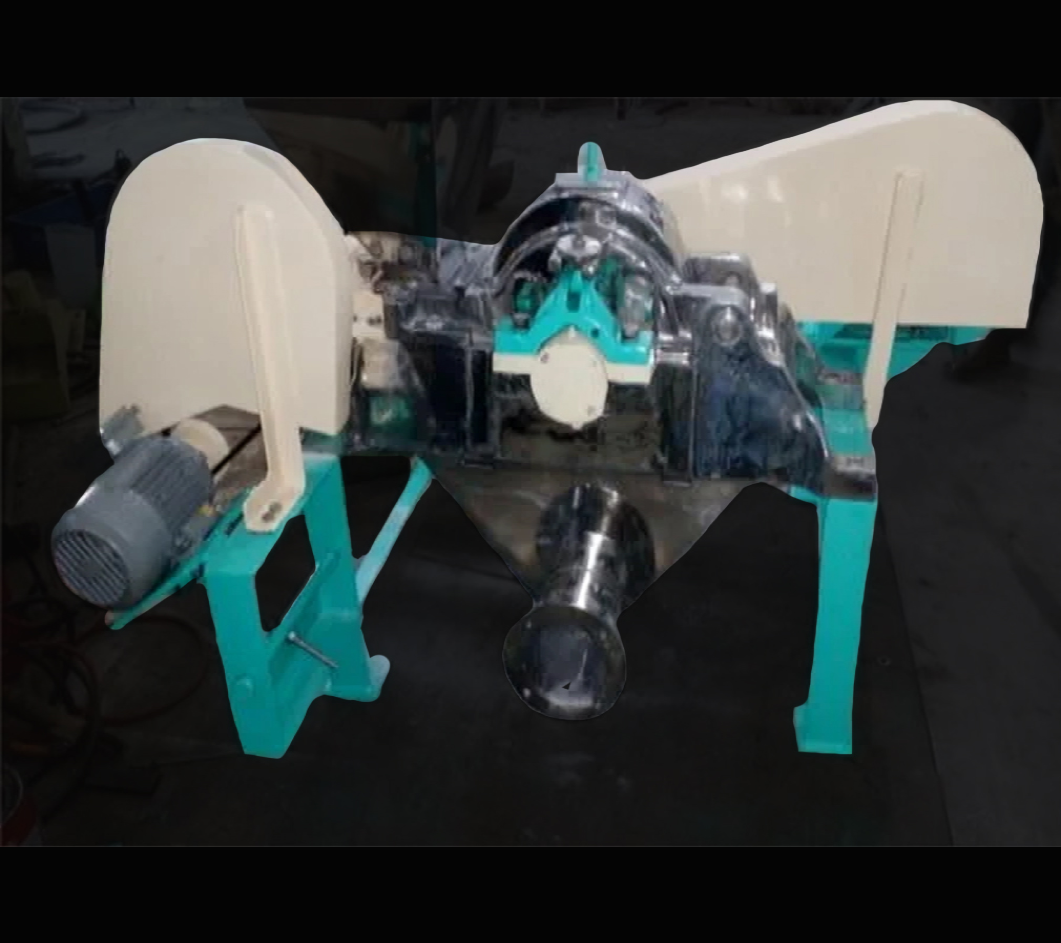

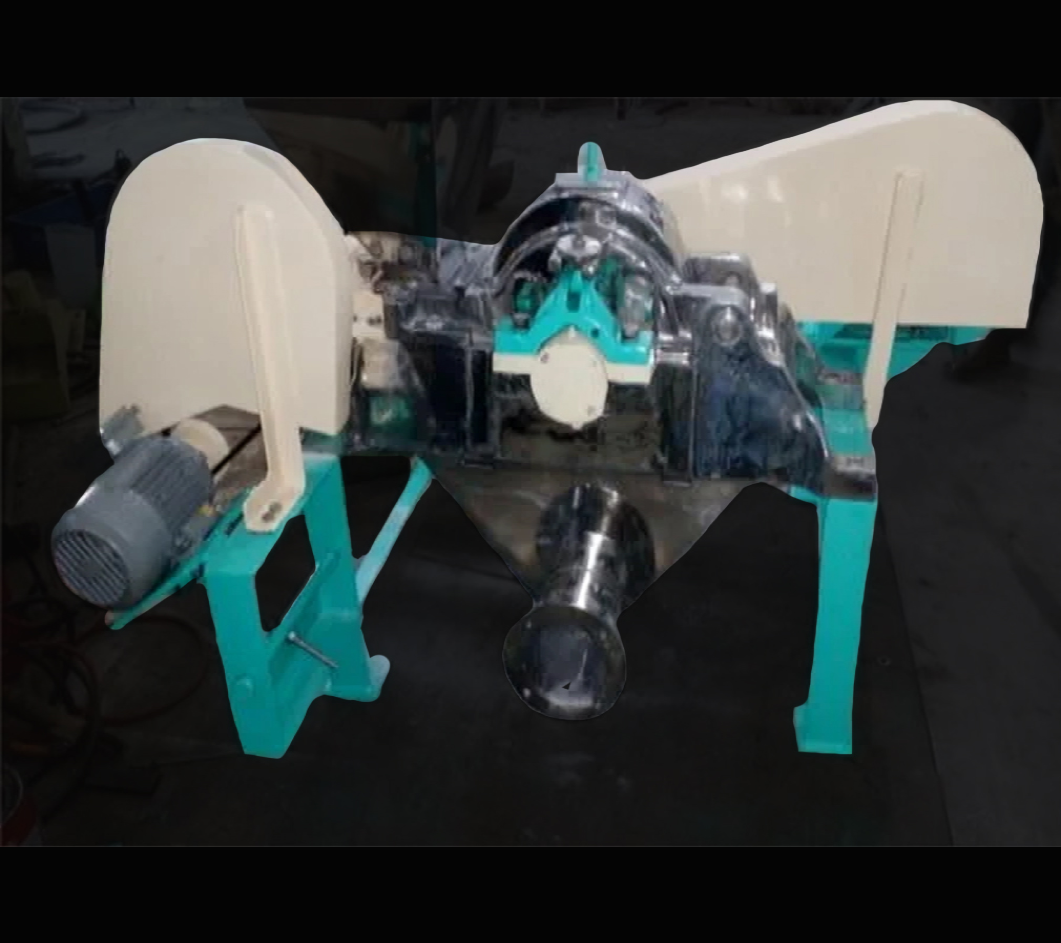

Micro Pulverizers

Micro Pulverizers :

Micro Pulverizers are advanced grinding machines designed for pulverizing a wide range of materials into ultra-fine powders. Ideal for industries such as pharmaceuticals, food processing, chemicals, and minerals, these pulverizers are engineered to deliver high-performance grinding with precise particle size control. The robust design and efficient grinding mechanism of Micro Pulverizers make them a perfect choice for applications requiring consistent fine powder output with minimal energy consumption.

- High-Efficiency Grinding: Micro Pulverizers use a high-speed rotor with fixed or swinging hammers to generate impact forces that pulverize materials into ultra-fine powders. This grinding mechanism is highly efficient, ensuring high throughput and uniform particle size distribution.

- Versatile Material Processing: Capable of handling a wide variety of materials, including soft, medium-hard, fibrous, and brittle materials. The Micro Pulverizers are suitable for processing spices, grains, pharmaceuticals, chemicals, and minerals, providing flexibility for various industrial applications.

- Adjustable Particle Size: Equipped with interchangeable screens and adjustable rotor speed, Micro Pulverizers offer precise control over the final particle size, from coarse granules to ultra-fine powders, ensuring the desired fineness for specific applications.

- Durable Construction: Built with high-quality materials such as stainless steel or carbon steel, Micro Pulverizers are designed to withstand the rigors of continuous industrial use, providing long-lasting durability and reliability.

- Compact and Space-Saving Design: The compact design of Micro Pulverizers makes them easy to integrate into existing production lines without requiring significant additional space, optimizing workflow efficiency.

- Low Energy Consumption: Optimized for energy efficiency, Micro Pulverizers operate with minimal power consumption while delivering high grinding performance, making them an economical choice for continuous fine grinding operations.

- Easy Maintenance and Cleaning: Designed for easy access to internal components, Micro Pulverizers allow for quick and straightforward cleaning and maintenance, reducing downtime and enhancing operational efficiency.

- Safety Features: Equipped with safety guards, emergency stop buttons, and overload protection to ensure safe operation and protect both operators and equipment.

- Hygienic Options: Available in food-grade and sanitary designs with smooth finishes and easy-to-clean features, making them ideal for applications requiring strict hygiene standards.

Micro Pulverizers are essential for any operation requiring precise and efficient grinding of materials into ultra-fine powders. With their robust construction, versatile applications, and advanced safety features, Micro Pulverizers provide a reliable and cost-effective solution for enhancing productivity and maintaining high standards of product quality across various industries.

Technical Specifications :

- Material of Construction: Stainless steel, carbon steel, or wear-resistant alloy steel

- Grinding Mechanism: High-speed rotor with fixed or swinging hammers

- Rotor Speed: Adjustable; typically ranges from 1,000 to 10,000 RPM

- Motor Power: Ranges from 5 kW to 75 kW, depending on the application and mill size

- Capacity: Up to 2,000 kg per hour, depending on material properties and fineness requirements

- Particle Size Range: Achievable particle sizes from 20 microns to 500 microns

- Feed Size: Up to 10 mm, depending on material and mill configuration

- Screen Size: Interchangeable screens with openings ranging from 0.2 mm to 5 mm

- Discharge Type: Gravity discharge or pneumatic conveying system

- Power Supply: 220V/380V, 50Hz/60Hz

- Noise Level: Below 85 dB

- Temperature Control: Integrated cooling system or jacketed design for temperature-sensitive materials

- Safety Features: Safety guards, emergency stop buttons, overload protection, and interlock systems

- Maintenance: Easy access for cleaning and maintenance; tool-free disassembly options

- Dimensions: Customizable; varies based on model and application

- Weight: Typically ranges from 300 kg to 2,000 kg, depending on size and configuration

- Control Options: Manual, remote, or PLC-controlled for automated operation

- Hygienic Design Options: Available in food-grade and sanitary designs with smooth finishes

- Compliance: Meets CE, FDA, and GMP standards

- Optional Accessories: Dust collectors, cooling systems, soundproofing enclosures, and variable frequency drives (VFD)