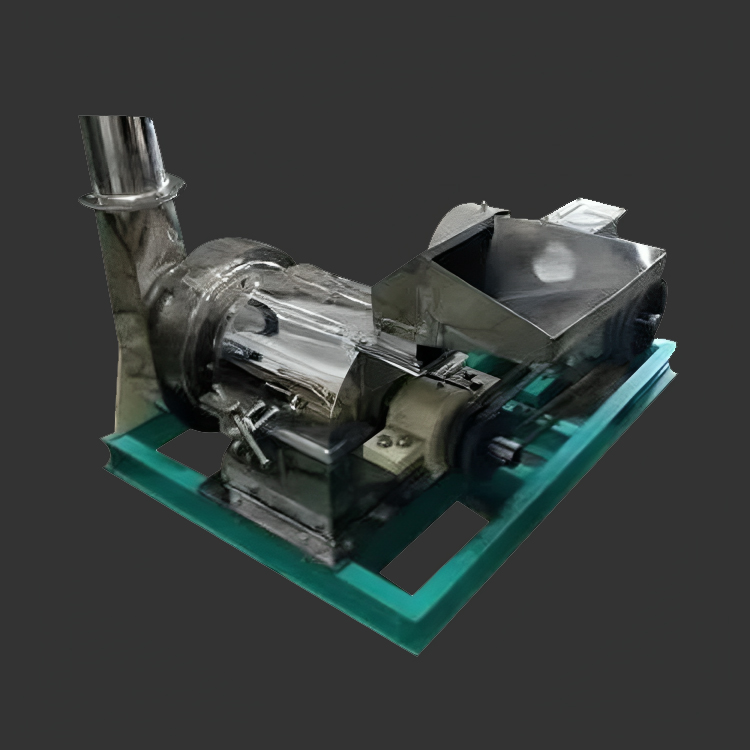

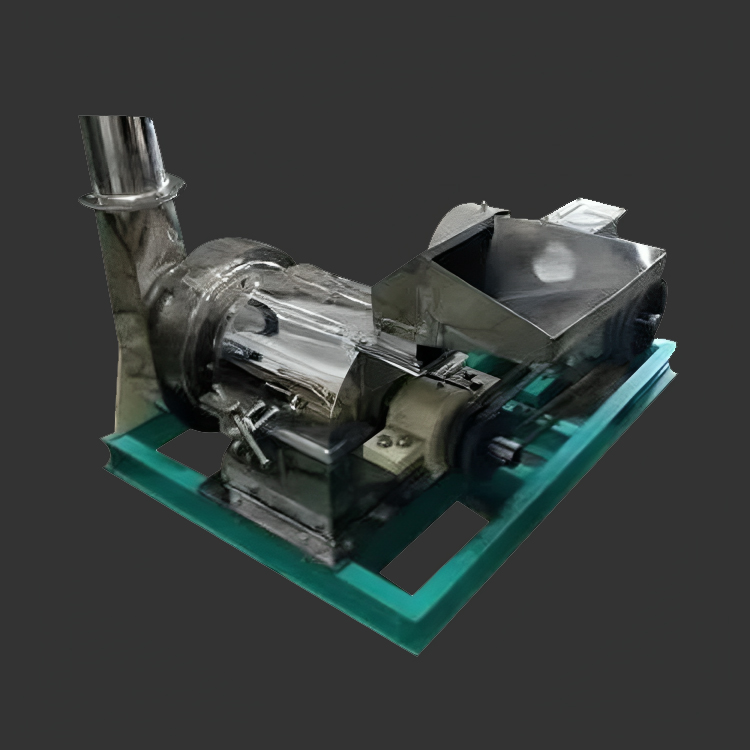

Air Swept Mill

Air Swept Mill :

The Air Swept Mill is a sophisticated grinding machine designed to achieve precise particle size reduction through a combination of impact and air classification. It is widely used in the chemical, pharmaceutical, food, and mineral industries for processing materials into fine powders. The mill’s design integrates air flow with mechanical grinding, enhancing the efficiency of particle size control and ensuring high-quality product output.

- Integrated Air Classification: The Air Swept Mill features an integrated air classifier that separates fine particles from coarser ones as they exit the grinding chamber. This dual-functionality ensures that only the desired particle size is collected, while coarser particles are returned for further grinding, optimizing the milling process.

- High-Efficiency Grinding: The mill utilizes a high-speed rotor with a series of hammers or blades to impact and pulverize materials. The combination of mechanical impact and air flow results in effective size reduction, making it suitable for a wide range of materials, including powders, granules, and fibers.

- Adjustable Particle Size: The Air Swept Mill allows for precise control over particle size through adjustable rotor speed and air flow settings. The mill can achieve particle sizes from 10 microns to 500 microns, providing flexibility for different applications.

- Versatile Material Handling: Designed to process various materials, including brittle, hard, and fibrous substances. It is ideal for grinding chemicals, pharmaceuticals, minerals, and food ingredients, offering versatility for multiple industrial applications.

- Efficient Air Flow System: The mill features a high-efficiency air flow system that ensures optimal air circulation and classification. The air swept design helps to cool the material during grinding and prevents the accumulation of heat-sensitive materials.

- Durable Construction: Constructed from high-quality materials such as stainless steel or carbon steel, the Air Swept Mill is built to withstand the rigors of continuous industrial operation. Its robust construction ensures durability and longevity.

- Compact and Space-Saving Design: The compact design of the Air Swept Mill allows for easy integration into existing production lines with minimal space requirements. This design optimizes workflow and maximizes production efficiency.

- Easy Maintenance: Designed with easy access to internal components, the Air Swept Mill allows for straightforward maintenance and cleaning. This design feature reduces downtime and ensures consistent operational performance.

- Safety Features: Equipped with multiple safety features, including safety guards, emergency stop buttons, and overload protection, to ensure safe operation and protect both operators and equipment.

- Hygienic Options: Available in food-grade and sanitary designs with smooth surfaces and easy-to-clean features, making it suitable for applications requiring high hygiene standards.

The Air Swept Mill offers an efficient and precise solution for fine and ultra-fine grinding applications. With its integrated air classification, high-efficiency grinding capabilities, and robust design, the mill provides a reliable and versatile option for achieving high-quality powder production in various industrial settings.

Technical Specifications :

- Material of Construction: Stainless steel, carbon steel, or wear-resistant alloy steel

- Grinding Mechanism: High-speed rotor with hammers or blades combined with integrated air classifier

- Rotor Speed: Adjustable; typically ranges from 1,000 to 7,000 RPM

- Motor Power: Ranges from 10 kW to 150 kW, depending on the application and mill size

- Capacity: Up to 5,000 kg per hour, depending on material properties and desired particle size

- Particle Size Range: Achievable particle sizes from 10 microns to 500 microns

- Feed Size:Up to 25 mm, depending on material and mill configuration

- Airflow Rate: Adjustable; airflow can range from 500 to 3,000 m³/h, depending on the model

- Discharge Type: Pneumatic or gravity discharge system

- Power Supply: 220V/380V, 50Hz/60Hz

- Noise Level: Below 85 dB

- Temperature Control: Integrated cooling system or jacketed design for temperature-sensitive materials

- Safety Features: Safety guards, emergency stop buttons, overload protection, and interlock systems

- Maintenance: Easy access for cleaning and maintenance; tool-free disassembly options

- Dimensions: Customizable; varies based on model and application

- Weight: Typically ranges from 500 kg to 3,500 kg, depending on size and configuration

- Control Options: Manual, remote, or PLC-controlled for automated operation

- Hygienic Design Options: Available in food-grade and sanitary designs with smooth finishes

- Compliance: Meets CE, FDA, and GMP standards

- Optional Accessories: Dust collectors, cooling systems, soundproofing enclosures, and variable frequency drives (VFD)